- Home

- Products

- Printing Machines

- Screen Printing Machine

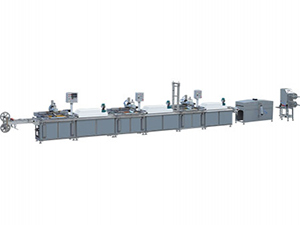

Screen Printing Machine

Minghui's screen printing machine consists of four sections: unwinding, printing, drying, and rewinding sections.

The drying section varies, depending on the color printing group. It includes a low-temperature dryer equipped behind every printing collection. Also, it has a large-temperature IR dryer behind all printing collections and in front of the rewinding systems.

The unwind and rewind systems are controlled by a stepping motor to avoid unstable printing caused by irregular tension.

The printing section is easily manageable. The ink is poured at one end of the screen-printing plate, and a squeegee (blade) is used to press down and drag ink across the screen. Then, the image transfers to the substrate through the opening areas of the screen. The repeat and pause time of the squeegee can be preset and controlled.

Every printer top can separately lift for smooth operation. The frame can also automatically elevate, convenient for ink drawing through a range, and mesh cleaning after printing.

Minghui also offers horizontal and vertical screen-printing machines.

MHS-126 and MHS-226 vertical screen-printing machines support one color and two-color printing.

With a compact design, and a smaller printing area and dryer system, these two screen printing presses are suitable for easy-to-dry materials. It supplies simple-printing images and low ink consumption mode.

The elastic ribbon is not appropriate for vertical screen printing.

MHS-300 horizontal screen printer is also available in Minghui.

-

- MHS-126/226 Screen Printing Machine

MHS-126 and MHS-226 vertical screen-printing machines support one color and two-color printing. Including a compact design, smaller printing area, and minor dryer system, these two screen-printing presses are suitable for easy-to-dry materials and applications with simple printing images and low ink consumption.

PLC electronic control system achieves manageable, reliable, and stable circuit control.

Cylinders are adopted to lift print heads and the mesh frame. Every print head can separately raise for smooth operation.

The frame can also lift automatically, convenient for mesh cleaning after printing. View All

-

- MHS-300 Screen Printing Machine MHS-300 horizontal screen- printing machine features complete automatic color register set up and electronic and mechanical integration systems. The high color register accuracy and excellent rapidness enable the printer ideal for large areas and dark substrate printing. The MHS-300 screen printing machine is exceptional at printing on a wide range of materials, including ribbon, rubber belt, woven label, leather, and others. According to the substrate material, application, ink thickness, color brightness, fastness and durability, different screen-printing methods and ink types can be chosen. Also, complete automatic constant printing on a roll-type belt substrate is available. View All

- Add.:

NO.209, Jinhu North Road, Jinhu Avenue, Ruian City, Zhejiang Province - Tel.: +86-577-65666005

+86-577-65666003 - Fax: +86-577-65666003