- Home

- Products

- Printing Machines

- Easy Registration Flexo Label Printing Machines

Easy Registration Flexo Label Printing Machines

The flexo label printing machines are presses which utilize anilox roller to transfer ink to the flexo plate and complete the printing process.

Minghui offers conventional flexo presses and auto-registration flexo printers. The auto-registration flexo printing-machine provides automatic registration, and it takes operators less time to learn how to operate it.

Although the auto registration flexo printer is expensive, it contributes to an increase in material savings, such as ink and web.

On the other hand, the standard flexographic printing machine is cheaper, and it requires to shut down for register, which demands longer learning time for operators.

Basic parts

- Unwind and infeed section

The roll of the web supplies with an optoelectronic switch for monitoring and detection. If the web is broken or runs out, and the optoelectronic switch can’t detect the web, the printing machine will automatically stop. - Printing section

The easy registration flexo printing-machine can print on both sides, which requires two respective cylinders where the anti-skid tape is applied to prevent web slippage. The number of ink fountains is determined by the number of colors used to print. i.e., each color ink is separately placed in different ink fountains. Suitable plate cylinders should be chosen to fit the trademark size. The number of cylinders of the same size is equal to the number of colors to be printed as well. The compressed air fixes the plate cylinder, and the flexo plate adheres to it for printing. - Drying section

The high-temperature air firstly dries the backside print of the substrate before the front side is printed. After both sides print, the substrate feeds through an IR dryer. - Rewind and outfeed section

The printed substrate rewound, and an optoelectronic switch is also adopted.

-

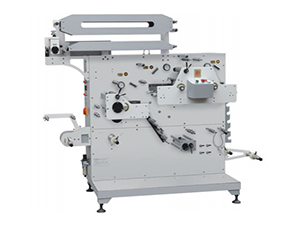

- MHR-S Flexo Label Printing Machine

The MHR-S flexo label printing machine utilizes a high-precision anilox roller to transfer the ink to the printing plate held on the plate cylinder, then the image is transferred to the image-receiving substrate.

After the substrate dries, the printing process finishes. Dozens of plate cylinders with a variety of specifications are available to satisfy the different printing requirements. Featuring an exact color register with a printing speed of up to 60m/min, the MHR-s flexo label-printing, can be a perfect alternative to screen printing machines.

View All

-

- MHR-B Series Flexo Label Printing Machine

MHR-B series flexo label printing machine is an upgrade for MHR-S flexo press, which can maintain registration without machine stop.

The MHR-B flexo label printing machine integrates mechanical and electronic technology, featuring stable printing pressure, accurate positioning, easy operations and high durability and reliability. This flexo label printer allows to adjust the position of plate cylinders without machine shut down and align them with the register marks. Thus a higher printing efficiency is achieved to save materials and reduce downtime. View All

Video

Minghui has over 20 years of experience in production of label printing machines and label finishing equipment. We are capable of supplying a variety of label printing equipment for flexographic printing, offset printing and screen printing adapted to your needs. Besides, we also supply a selection of label cutting machines suitable for various roll-to-roll label printing and narrow web printing machines for implementing of cutting to size. Focused on providing return on investment for customers, we develop and manufacture our label printers in house and provide services covering training, maintenance and spare parts. We at Minghui are pleased to give you very best service and support.

- Add.:

NO.209, Jinhu North Road, Jinhu Avenue, Ruian City, Zhejiang Province - Tel.: +86-577-65666005

+86-577-65666003 - Fax: +86-577-65666003